As demand for gallon water bottles continues to rise for homes, offices, and commercial water dispenser services, many businesses are looking to set up pet bottle production line for large-capacity bottled water. But what exactly is involved in making these bottles, and what equipment do you need to start manufacturing them?

In this guide, we’ll introduce the essential equipment needed to produce gallon water bottles, explain how they’re made, discuss their applications, and highlight why investing in an automatic bottle blowing machine is the most efficient solution.

How Are 5-Gallon Water Bottles Made?

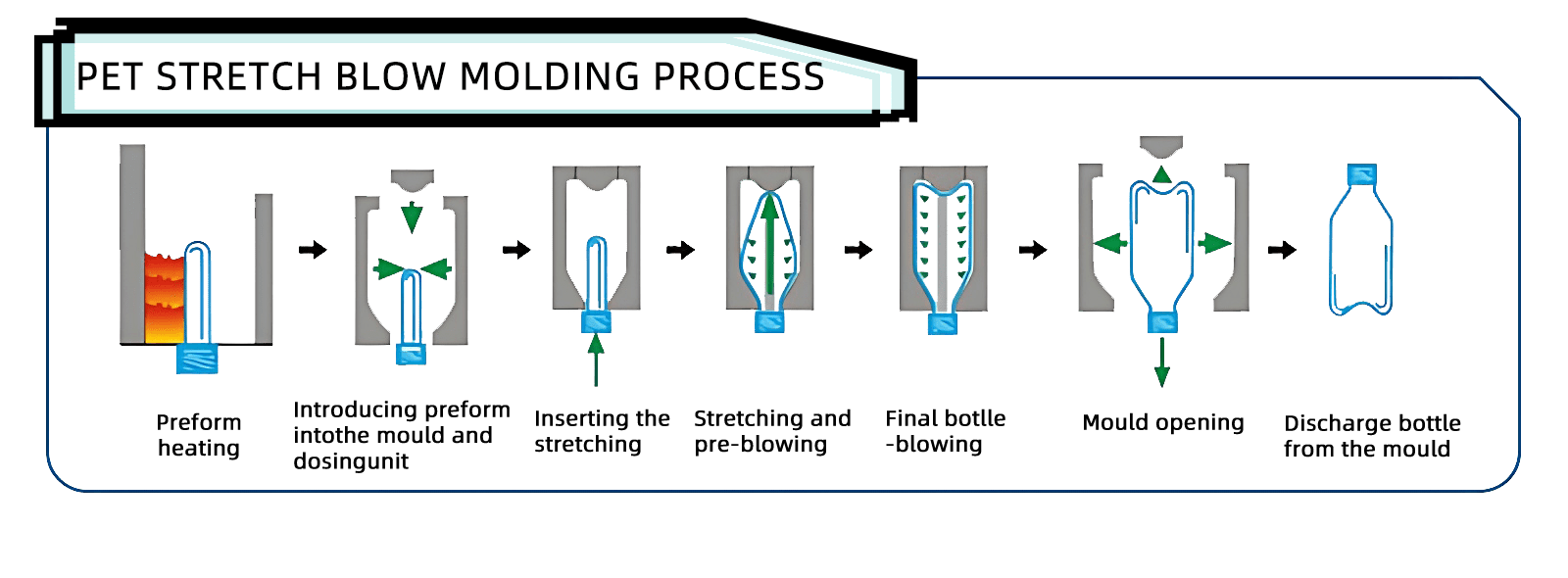

Plastic gallon water bottles are typically made from durable, food-grade plastics such as PET (Polyethylene Terephthalate), PC (Polycarbonate), or HDPE (High-Density Polyethylene). The bottles are manufactured using a process called blow molding — where a heated preform is inflated into a mold using high-pressure air.

Manufacturing Process:

-

Preform Heating: Small plastic preforms (resembling test tubes) are heated to the optimal temperature for softening.

-

Blow Molding: The heated preform is placed into a mold designed for a 5-gallon bottle.

-

High-Pressure Air Injection: Compressed air is used to expand the preform into the shape of the mold.

-

Cooling: The newly formed bottle is cooled to set its shape.

-

Trimming & Inspection: Excess plastic is removed, and bottles are checked for leaks or defects before packaging.

What Equipment Is Needed to Produce 5-Gallon Water Bottles?

To successfully set up a gallon water bottle production line, several key machines and systems are required:

1. Preform Injection Molding Machine

-

Converts raw plastic pellets into bottle preforms.

-

Ensures consistent quality and preform dimensions for blow molding.

2. Automatic Bottle Blowing Machine

-

The core machine for transforming preforms into finished 5-gallon bottles.

-

Features:

-

High-speed production

-

Consistent wall thickness

-

Capable of handling larger bottle volumes (3–5 gallons)

-

Minimal manual labor needed

-

3. Air Compressor System

-

Provides the high-pressure air required to inflate preforms into the mold.

4. Bottle Mold Sets

-

Custom-designed molds to shape the 5-gallon bottles.

-

Available for standard 3-gallon and 5-gallon sizes, or customized designs.

5. Trimming and Leak Testing System

-

Removes extra plastic material from bottle necks.

-

Automatically tests bottles for air-tightness and leaks.

6. Conveyor and Bottle Handling Equipment

-

Moves bottles efficiently between production stages.

-

Can be automated for high-volume operations.

How Much Is a 5-Gallon Water Bottle?

Prices for 5-gallon water bottles vary depending on material, quality, and whether the bottle is new, refillable, or sold with water included.

| Type | Average Price (USD) |

|---|---|

| Empty 5-gallon PET bottle | $6 – $9 |

| Empty 5-gallon PC bottle | $8 – $12 |

| Filled 5-gallon water bottle | $7 – $15 |

Factory production costs are typically much lower per bottle, especially when produced in bulk.

What Can 5-Gallon Bottles Be Used For?

While commonly associated with bottled drinking water, 5-gallon bottles are versatile containers used for a variety of purposes:

-

Office and home water dispensers

-

Bulk water delivery services

-

Emergency water storage

-

Outdoor events, camping, or sports hydration

-

Industrial liquids or chemicals

-

DIY projects, planters, or rainwater collection systems

How to select a 5-Gallon Bottle Making Machine

When choosing a 5-gallon bottle making machine, consider the following:

-

Material compatibility: Can the machine handle PET, PC, or HDPE?

-

Production capacity: Bottles per hour

-

Machine automation level: Semi-automatic vs. fully automatic

-

Custom mold options

-

After-sales support: Service, spare parts, and technical assistance

Why Choose an Automatic Bottle Blowing Machine for 5-Gallon Bottles?

An automatic bottle blowing machine is essential for efficiently producing high-quality gallon bottles. Here’s why:

Key Benefits:

-

High-speed production: Capable of producing up to 600 bottles per hour

-

Consistent quality: Ensures uniform wall thickness and shape

-

Lower labor costs: Automated systems reduce manual handling

-

Lower defect rate: Accurate blow molding minimizes rejected bottles

-

Adaptable: Can produce different sizes (3-gallon to 5-gallon) by changing molds

For water bottling factories, investing in a reliable automatic gallon water bottle blowing machine ensures long-term cost savings and product consistency.

Pro Tip: If you’re planning a full production line, make sure your equipment supplier can provide integrated solutions — from preform injection to blow molding, trimming, and leak testing.

Conclusion

If you’re considering entering the bottled water industry or expanding your production capacity, investing the right 5-gallon water bottle making machines is essential. By using automatic bottle blowing machines and reliable production equipment, you can improve efficiency, lower operational costs, and deliver consistent, high-quality bottles for your customers.

Need Help Choosing Machines? Contact us for tailored solutions—whether you’re manufacturing 200ml, 500ml, 2L, 5L, 10L, 20L Bottles!