Description

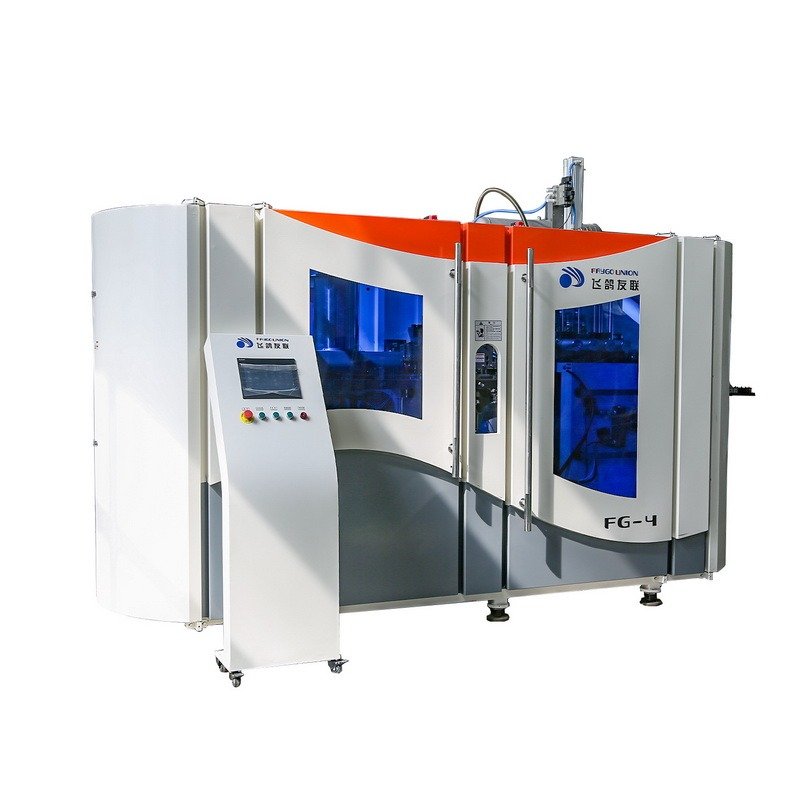

Automatic Water Bottle Blowing Machine

Faygo Union specially designed the most stable two-step high speed automatic liner bottle blow molding machine for blowing pet bottles. This Automatic PET bottle blowing machine, whose single-mold speed can reach 2500~3000BPH. FG series bottle blowing machine include three model right now: FG4 (4-cavity), FG6(6-cavity), FG8 (8-cavity). The max speed could be 16000BPH (High Speed blow molding machine).

This FG4 (4-Cavity) automatic water bottle blowing machine, The capacity can be 6800-8000BPH. and the maximum capacity of the products is 2L. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, and other packing containers.

With trustworthy excellent method, very good standing and excellent client provider. For 4- Cavity Fully Automatic Plastic Bottle Blowing Machine, If you are fascinate in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly. we will reply you within just 24 hours and also the best quotation might be provided.

Short Lead Time for China Plastic Machine and Blow Molding Machine, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

This series of models mainly produces PET plastic bottles, pure water, mineral water PET bottles, and beverage bottles.

It is developed totally independently, has our own intellectual property rights and has obtained more than 13 national patents.

FG series bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power and low compressed air consumption. Feature the excellent structure design, small space occupation, less noise and high stability, meanwhile conforms to national beverage sanitary standards. This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium and large enterprises.

Parameters of Faygo Union Automatic PET Bottle Blowing Machine

| Model | FG4 | FGX4 | FG6 | FGX6 | FG8 | FGX8 | ||

|---|---|---|---|---|---|---|---|---|

| Mold number(piece) | 4 | 4 | 6 | 6 | 8 | 8 | ||

| Max capacity(BPH) | 7200 | 8500 | 9600 | 12000~130000 | 12000 | 15000-16000 | ||

| Bottle specification | Max volume(ml) | 2000 | 2000 | 2000 | 2000 | 2000 | 750 | |

| Max height(mm) | 328 | 328 | 328 | 328 | 328 | 300 | ||

| Round bottle max diameter(mm) | 105 | 105 | 105 | 105 | 105 | 75 | ||

| Preform specification | Suitable inner bottle neck(mm) | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | |

| Max preform length(mm) | 150 | 150 | 150 | 150 | 150 | 150 | ||

| Electricity | Total installation power(kW) | 51 | 51 | 74 | 97 | 97 | 97 | |

| Heating oven total power(kW) | 46 | 46 | 69 | 92 | 92 | 92 | ||

| Heating oven real power(kW) | 26 | 26 | 40 | 42 | 50 | 48 | ||

| Voltage/frequency(V/Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | ||

| Allowed voltage fluctuation range | ±10% | ±10% | ±10% | ±5% | ±10% | ±10% | ||

| Compressed air | Pressure(bar) | 30 | 30 | 30 | 30 | 30 | 30 | |

| Air consumption(㎥/min) | 4 | 6 | 5.5 | 8~10 | 7 | 10 | ||

| Cooling water | Mold water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 |

| Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | ||

| Flow rate(L/min) | 45 | 45 | 45 | 45 | 45 | 45 | ||

| Oven water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | |

| Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | ||

| Flow rate(L/min) | 22 | 22 | 22 | 45 | 22 | 45 | ||

| Machine specification | Machine dimension(m)(L*W*H) | 3.3*1*2.3 | 4.6*1.3*2.3 | 4.3*1*2.3 | 5.5*1.3*2.5 | 5.5*1.3*2.5 | 5.5*1.3*2.5 | |

| Machine weight(Kg) | 3500 | 4500 | 4500 | 6500 | 6500 | 6500 |

Reviews

There are no reviews yet.