Why Do Most Mineral Water Beverage Bottles Use PET Material? How PET Bottles Are Made

Introduction

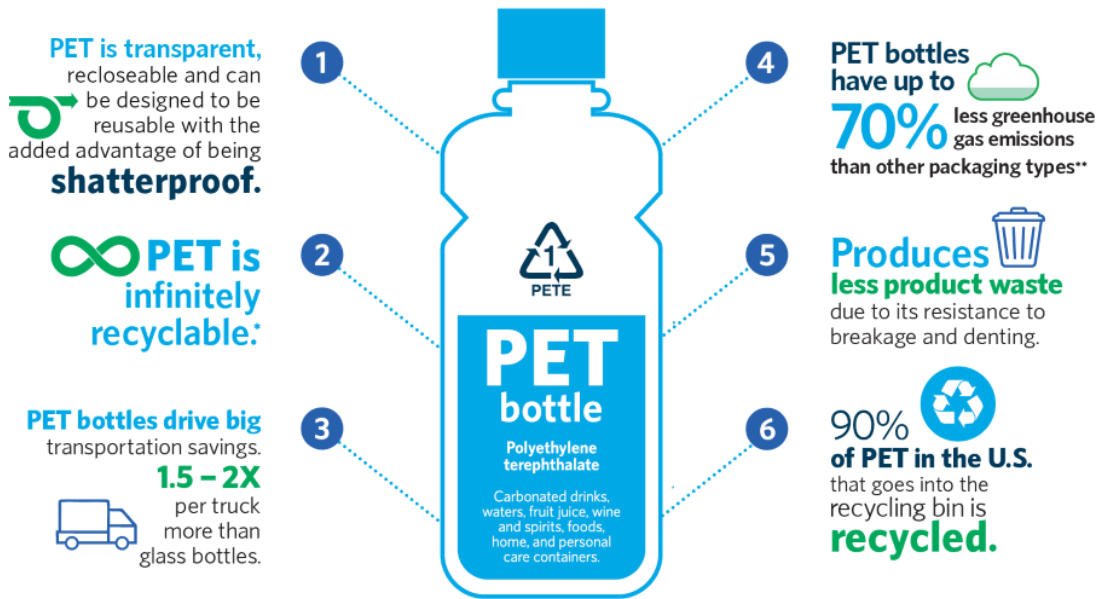

When you walk into a supermarket, convenience store, or vending machine, you’ll notice that the majority of mineral water bottles are made from PET (polyethylene terephthalate) plastic. But why is this material so widely used in the beverage industry? And how PET bottles are made to meet the demands of safety, durability, and cost-efficiency?

This article will explore what PET material is, why PET bottles dominate the mineral water market, the advantages of PET bottles, whether PET water bottles are safe, and a step-by-step look at the PET bottle manufacturing process. Finally, we’ll also discuss recyclability and sustainability aspects that make PET bottles a key player in modern packaging.

What Is PET Material?

PET (polyethylene terephthalate) is a type of thermoplastic polymer belonging to the polyester family. It is made by polymerizing ethylene glycol and terephthalic acid—both derived from petroleum refining.

PET is widely used in:

Mineral water bottles

Carbonated soft drink bottles

Food packaging containers

Fibers for textiles (polyester fabrics)

Key Properties of PET:

Lightweight yet strong – PET bottles are much lighter than glass, reducing transport costs.

Transparent – PET offers a clear, glass-like appearance.

Barrier resistance – PET prevents oxygen from entering and carbon dioxide from escaping, keeping beverages fresh.

Safe for food contact – Recognized as safe by regulatory agencies like the FDA and EFSA.

Because of these characteristics, PET quickly became the industry standard for bottled water, soft drinks, juices, and other beverages.

Why Do Most Mineral Water Bottles Use PET Material?

Most mineral water bottles on the market use PET material because it combines safety, strength, and cost-effectiveness. PET is lightweight yet durable, making bottles easy to transport and resistant to breakage compared with glass. This is especially important for large-scale beverage companies that prioritize efficiency in logistics and distribution.

Another key reason is safety and hygiene. PET is non-toxic, BPA-free, and approved by health authorities worldwide for food and beverage packaging. It does not affect the taste or purity of mineral water, ensuring consumers get clean, fresh drinking water.

From a manufacturing perspective, PET bottles are highly versatile. They can be produced quickly and in different shapes and sizes through efficient blow molding processes, which reduces production costs. PET also offers excellent clarity, allowing brands to showcase the water’s quality and purity.

Advantages of PET Bottles for Mineral Water Packaging

| Advantage | Description |

|---|---|

| Lightweight | Reduces transportation costs and improves consumer convenience |

| Strong & Pressure-Resistant | Withstands carbonation pressure and rough handling during shipping |

| Transparent | Maintains the premium look of pure, clear mineral water |

| Cost-Effective | Lower raw material and production costs compared to glass or aluminum |

| Food-Safe | Approved for direct contact with water and beverages |

| Recyclable | PET is 100% recyclable and widely collected across the globe |

| Versatile Design | Available in multiple sizes and shapes for brand customization |

How PET Bottles Are Made

Understanding how PET bottles are made provides insight into why they are so durable, cost-efficient, and popular.

Step 1: PET Preform Production

The process begins with PET resin pellets.

These pellets are melted and injected into molds to form preforms—test-tube shaped plastic pieces with a neck finish already formed.

PET preform making machines handle this step.

Step 2: Stretch Blow Molding

Preforms are heated to a precise temperature.

Using a PET bottle blowing machine, compressed air stretches the preform into the shape of a bottle.

The stretching process strengthens the molecular structure, allowing the bottle to resist internal pressure.

Step 3: Cooling and Shaping

Once blown, the bottles are quickly cooled to lock the shape.

Quality checks ensure wall thickness, weight, and transparency meet standards.

Step 4: Filling and Capping

Bottles are transferred to a mineral water bottling machine or water filling equipment.

The bottles are rinsed, filled with mineral or purified water, and sealed using bottle cap making machines.

Labels are applied, and packaging is prepared for shipping.

Are PET Bottles Recyclable?

Yes, PET bottles are 100% recyclable. In fact, PET is the most recycled plastic in the world.

Recycling Process:

-

Collection & Sorting → Bottles are separated from other waste.

-

Cleaning & Shredding → Bottles are washed and shredded into flakes.

-

Melting & Re-extrusion → Flakes are melted and made into new PET products.

Recycled PET (rPET) Applications:

-

New PET bottles

-

Food packaging

-

Polyester fibers (used in clothing, carpets, etc.)

-

Automotive components

Future of PET Bottles in the Beverage Industry

While alternatives like aluminum cans, glass bottles, and paper-based packaging are emerging, PET continues to dominate due to its balance of performance, safety, and cost-efficiency.

Future trends include:

More use of rPET to reduce plastic waste.

Lightweight bottle design to further cut carbon emissions.

Smart packaging innovations like QR codes and tamper-proof designs.

Conclusion

Most mineral water bottles on the market use PET material because it is lightweight, durable, transparent, safe, cost-effective, and recyclable. Consumers trust PET for its safety and clarity, while manufacturers rely on it for efficiency and branding flexibility.

The process of how PET bottles are made—from preform molding to stretch blow molding and bottling—further ensures that the final product meets both safety standards and market demands.

As sustainability becomes more important, PET bottles remain a crucial packaging solution, especially when combined with effective recycling programs. Whether you’re a consumer curious about the safety of your bottled water or a business exploring packaging options, PET continues to be the most practical choice for mineral water and beyond

Faygo Union’s PET Bottle Solutions

At Faygo Union, we specialize in advanced PET bottle production technology. We have Automatic PET bottle blowing machine and high-speed pet blowing machine, we help you produce safe, high-quality PET bottles that meet global standards.

👉 Whether you’re starting a new bottled water plant or upgrading your beverage drink production line, Faygo Union provides turnkey solutions tailored to your needs.